During the production process, machines, machine parts and the rest of the plant can become extremely dirty. Manual cleaning takes a lot of time. Multi Masters Group offers a quicker and harmless alternative: dry ice blasting.

Dry ice blasting: how does it work?

Dry ice – also called ‘carbon dioxide snow’ – is carbon dioxide or CO2 in solid form. The CO2 gas is cooled to -79° C and compressed into pellets. That are small ‘balls’ with a diameter of about three millimetres.

In dry ice blasting or ice cleaning, these pellets are projected onto the contaminated surface with the help of compressed air. The cleaning process with dry ice consists of three phases:

- Mechanical phase: the dry ice pellets collide with the contamination at high speed, thus damaging it.

- Thermal phase: the low temperature of the pellets (-79° C) further affects the contamination (thermoshock). This causes it to crack.

- Sublimation phase: when the pellets come into contact with the surface (the contamination), they change from a solid form into a gas (sublimation). Because of that the volume of the pellets to increase enormously. As a result, the already damaged contamination will ‘explode’, as it were.

These 3 phases cannot be observed with the naked eye. They take place in a fraction of a second.

What do you need for dry ice blasting?

For dry ice cleaning you need a compressor, a tank with pellets, a dry ice blasting unit and a person to operate the unit.

Where can you apply this cleaning method?

Dry ice blasting can be used in the most diverse sectors. For instance, the food sector, the chemical industry, the graphic industry, monument conservation, the automotive sector, the textile industry, etc. The applications are virtually endless. Think, for instance, of the cleaning of production lines, moulds, printing presses, control panels, electric cables, engines and parts, undercarriages of trains, buses, trams, etc. With dry ice pellets, the most diverse, stubborn contamination can be removed, such as plastic, oil, grease, resin, glue, ink, paint, chewing gum, etc.

What are the advantages of dry ice cleaning?

- Environmentally friendly: no chemicals are used in dry ice blasting.

- No added waste: after cleaning, the loosened waste can simply be swept away with a brush. Because the pellets sublimate into CO2 gas during the process, there is no additional waste. With sand or water jets, the sand or waste water must be disposed of after cleaning. With dry ice cleaning, this is not an issue at all.

- Minimal downtime: machines do not need to be disassembled and reassembled for cleaning. As the pellets sublimate into gas, they penetrate into the smallest corners.

- Harmless: it is a completely dry cleaning process and it is also harmless (not abrasive) for the surface to be cleaned. This type of cleaning is therefore extremely suitable for vulnerable materials (e.g. soft aluminium, chrome, natural stone,…) and even for electric cables and electronic components of machines.

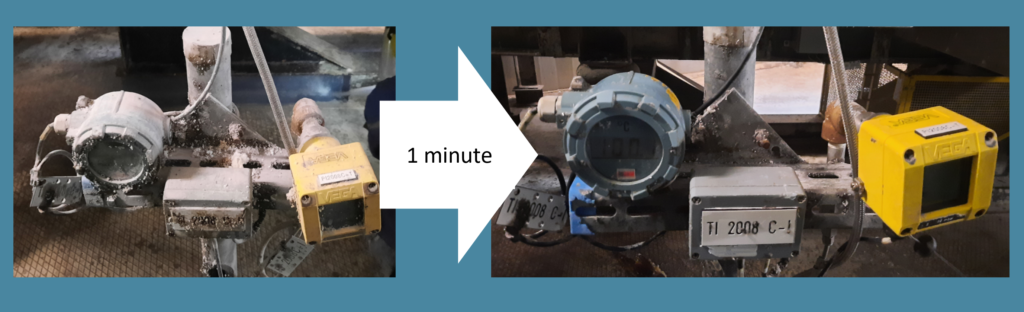

- Speed: cleaning with dry ice is more than ten times faster than cleaning the same surface manually.

Are there any disadvantages to this type of cleaning?

Of course dry ice cleaning is more expensive than manual cleaning. That is logical: you need dry ice pellets, a compressor and a dry ice blasting unit. However, you get a lot back for that. As said, machine cleaning is much quicker than manual cleaning. The cleaners can therefore work much faster. Besides, the production stops much shorter, so your effective production time increases. Dry ice cleaning is also more thorough, which extends the life span of your infrastructure considerably. Finally, this cleaning is environmentally friendly, so it is better for the well-being and the health of your employees.

Are you interested in dry ice cleaning? Please contact us.

More videos about dry ice blasting? Take a look at the YouTube channel of our partner Cold Jet.